[Story of Amber #1] 6 Questions to Ask When Choosing a Millable Lithium-Disilicate Glass-Ceramic

- Date : 2022.04.20

6 Questions to Ask When Choosing a Millable Lithium-Disilicate Glass-Ceramic

Material selection is vital in any restorative or smile design case in order to achieve satisfactory long-term results for the patient. With the variety of restorative materials available to dentists and technicians today, dental professionals must be sure that the material chosen will withstand the masticatory forces placed on it, that it produces optimum aesthetics, is an easy user-friendly system and of a reasonable cost.

DB Lab Supplies highlights the six key questions for dental technicians when choosing a lithium disilicate, and explains how Amber Mill, a versatile restorative material from Hass Bio, provides a predictable and easy to use protocol for achieving high aesthetics, and a radically reduced inventory. How does your existing lithium disilicate fare?

1. Can it lower my inventory?

A system that offers multiple translucencies with minimal stock varieties keeps your inventory costs low. Amber Mill is the only brand that promises 4 opacities from one block.

Simply purchase the shade, then choose the correct firing cycle to obtain the required opacity. Amber Mill offers 19 shades in total; including 4 whitening shades.

2. Is it user-friendly?

From mill to pre-polish and glaze, cofiring and try-in, each step can be simple and efficient. Being able to change the opacity simply by re-firing without remaking will enhance the efficiency of your working process, in addition to lowering your inventory.

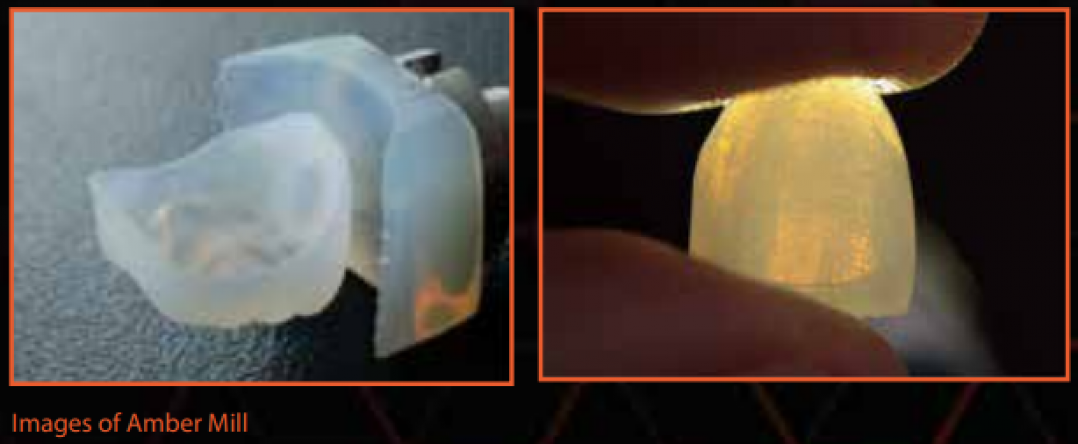

Amber Mill’s machinable nano lithium disilicate block offers an unprecedented level of quality and efficiency in comparison to other recent dental materials. Prepolishing and co-firing techniques allow users to obtain a streamlined process with shorter working times.

Co-firing of Crystallization and Stain/Glazing

Often, conventional lithium disilicates cannot control the thickness and contents of stains due to the low opacity and bluish colour of crowns.

How does Amber Mill differ?

Amber Mill combines the crystallisation and stain/glaze firing in one step with a stain paste/glaze spray.

Pre-polishing after CAD/CAM machining

Pre-polishing at glass-based state before final crystallisation firing allows users to obtain a natural glossy surface on crowns. The fine crystal size of Amber Mill lithium disilicate increases the lustre after final crystallisation firing.

3. Can it deliver high aesthetics?

Choose a Lithium disilicate with proven high aesthetic results in a variety of disciplines. Lithium disilicate can offer a superior combined balance of physical properties and aesthetic values.

4. Does it offer reliable machinability and edge stability?

Raise your expectations of what a lithium disilicate can offer. Look for a material that is proven to achieve highly stable edges and a minimal chipping occurrence. Amber® Mill is a highly durable and reliable machinable lithium disilicate block proven to deliver these indicators.

5. Is it durable enough for posterior?

Historically, lithium disilicate has come under scrutiny for its potential for failure when used in the posterior region.

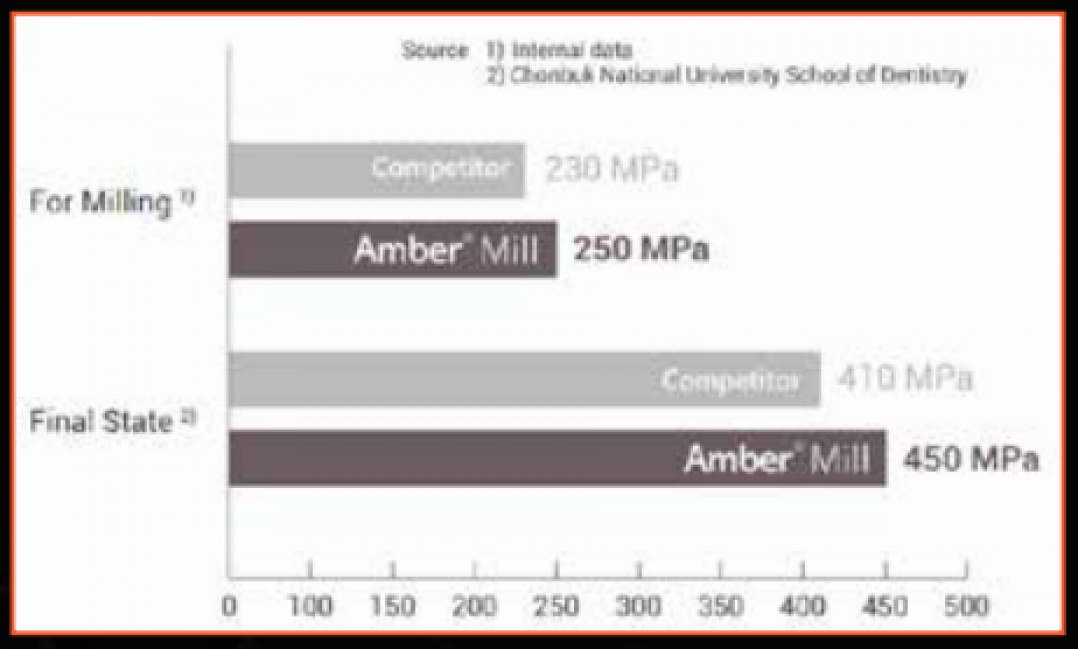

Yet, Amber Mill’s denser and more crosslinked crystal structure results in superior physical properties. The biaxial flexural strength of Amber® Mill is about 10% higher than comparative product after it is fully crystallised.

6. What do other the Technicians say?

“I quickly found out the benefits this material has to the technicians working with it. There is 1 block of material per shade but the firing cycle on the laboratory’s side predicts 4 different levels of opacity. From a milling point of view, this means that using this material reduces stock levels by at least half! Amber Mill possesses a more detailed edge definition, and increased bur yield over other products we have milled in the past.”

Raymond Otto, Zfx UK Milling Centre Owner.

“First of all, I can say that for over 5 years I have been treating cases with Amber, and when patients come back for review, we always see the same aesthetic results as if it was the first day of treatment … The dental technician has the flexibility to work within both disciplines (analogue and digital) and achieve the same results. Also, the technician can combine a mixed protocol.”

Cristian Petri, Award winning Dental Technician, Amber Ambassador and World Speaker.

Discover Amber Mill

With optimum aesthetics, workflow and its unique ability to produce multiple shades from one block, unquestionably, Amber Mill takes lithium disilicate fans to the next step in the evolution of CAD/CAM dentistry

*source : https://www.dblabsupplies.co.uk/